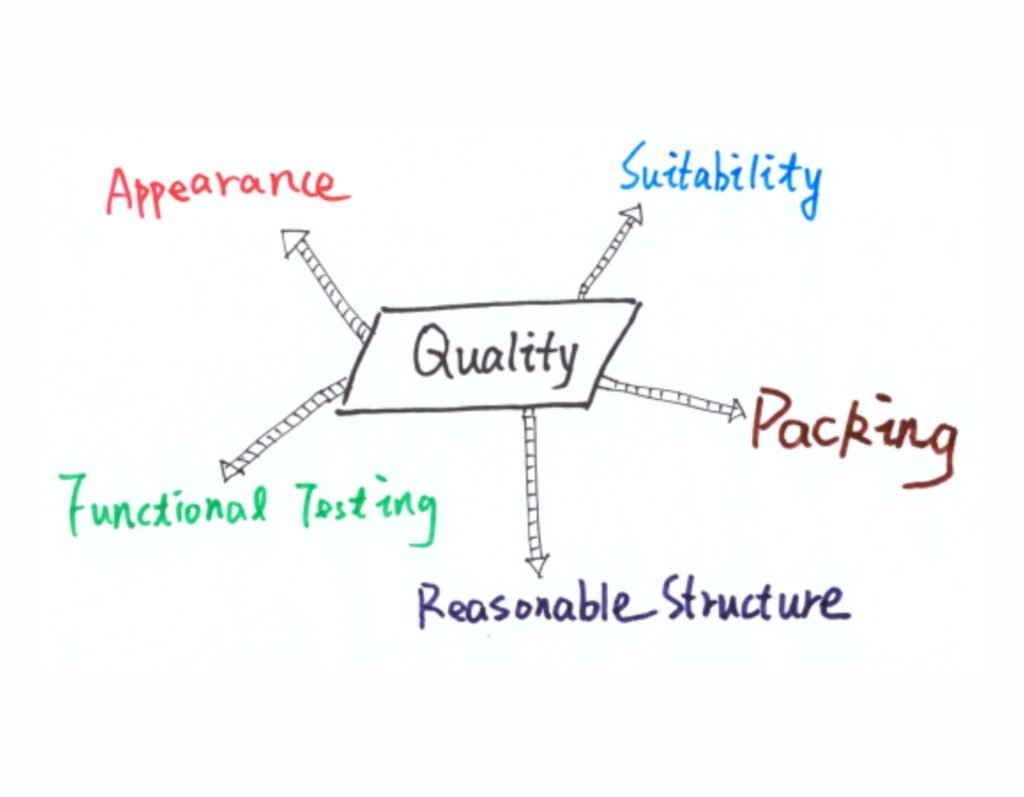

First of all, judging the quality of the display stand is a quite big topic, because of its material diversity, the structure is different, each display rack is unique and customized. When we are relatively unfamiliar to purchase the display rack, how can we professionally judge the quality of the display rack is OK?

The following we will from every detail to express the quality of the display standard, we believe that after reading this article, you will have a better understanding of the purchase of the display stands and have certain control of the quality.

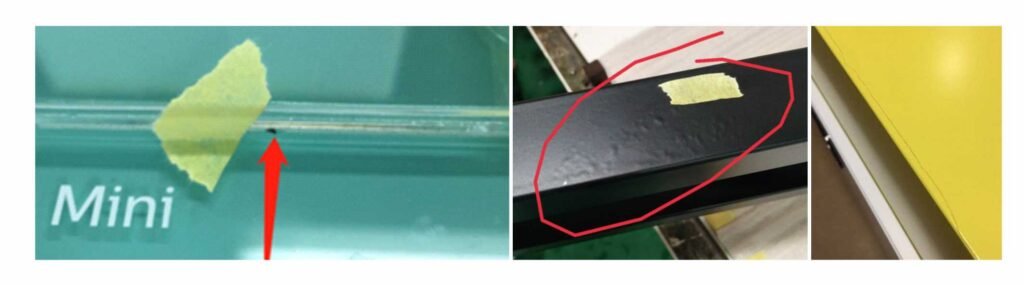

1, Appearance

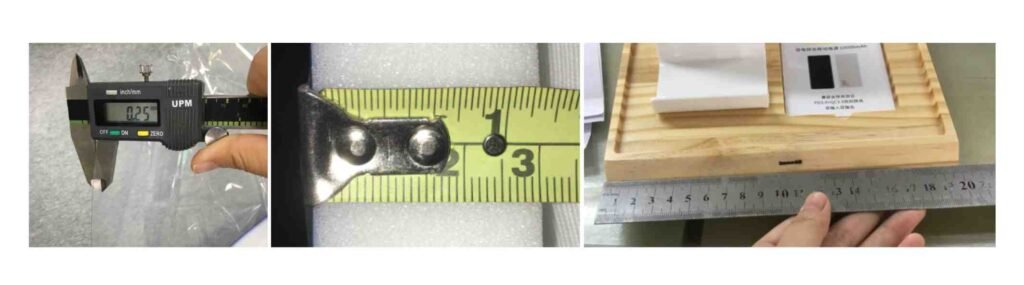

This should be done from multiple angles, such as size, material, color, direction, text, surface…

Size: Overall dimensions; Hole location size; The thickness; Logo and painting size; Internal detail dimensions. All dimensions should be consistent with the design.

Material: acrylic, wood(MDF, Polywood, Solid wood), PVC foam board, paper, metal, ss steel, etc.

Color: Spray painting color, Screen color contrast Pantone, Lighting color, UV print color, Graphic color.

Direction: Direction of stickers, Woodgrain direction, Product placement sequence.

Text: all of the artwork, specifications, and logo all with text should check whether it has any missing or wrong.

Surface: Acrylic – scratch, glue overflow. / Metal – paint spray surface effect / Wood – chipped edges or cracked paint.

2, Suitability

Display frame assembly adaptation: the display frame is generally in order to consider the reduction of transport volume, general assembly structure to reduce the size of the packaging, so you need to have the installation instructions, according to the above steps to assemble. If you can successfully assemble is OK, on the contrary, if the screw hole position is not on, it must be NG.

Products suitable for display: custom exhibition stand our main purpose is to better show our unique products in the above, the product must be able to put right or assembly up. If the hole is a little small will lead to products can not put on, or the hole is too big, which can affect the beauty as well as the overall effect. Generally, it is best to follow the physical products to test holes and positions.

3. Functional Testing

The general function has the LED lighting, an LCD screen, a PCB board which to test the sound of the speakers and headsets, or the part of the display rack that needs waterproof, heat resistance, and some other performance tests.

Here about the speakers display stands, generally, it will display the function of the sound: play/pause, the next song, volume +/-, the control of the buttons to the corresponding function, the other special requirements of special customization, for this kind of exhibition stand before packaging needs 100% in accordance with the requirements for function test.

4. Reasonable Structure

Is there any safety problem with the display rack after assembly? Will the floor display rack fall down easily?

Whether to put the product will affect the experience effect?

Can we improve the structure to make the assembly more convenient?

Perhaps a change of material could reduce costs?

Is the wiring inside neat and convenient for later replacement?

Is the fixed LCD screen or PCB board strong enough that it will not come off in express delivery?

The assembly welds are strong enough?

5, Packing

Packaging is one of the most critical and most easy to ignore, each display rack is customized, which means that each packing is also customized, wrong packaging in the supply chain will cause great losses.

When opening the packaging, we should also check whether each accessory are complete, the equipped screws are best to be stainless steel material, such as some lock the back of the butterfly screws with nickel plating material, will soon have the phenomenon of rust, will affect the appearance of the penny-wise and pound-foolish.

The general way of packing for the set is PP bag, pearl cotton, then into the carton, some special display stands the way we can also use a drop test to see whether it’s security, the benefits of the drop test can also verify adhesive exhibition stand itself firmly if fall there is parts fell behind, and that this place should be strengthened and firm, and exhibition stand if where there is damage to the appearance, The place should strengthen the protection of packaging.

Further information on display stand packing way can ref https://xminusdisplay.com/pack-battery-display/

Learn the above 5 aspects(Appearance, Suitability, Functional Testing, Reasonable Structure, Packing), believe that we already have a certain concept of the judgment of the display rack. If we want to have a deeper understanding, still need to accumulate rich experience in a number of projects. Each customized display rack will bring us different inspirations.

Further questions about the display racks, please feel free to discuss with us. Xminus team is always here.

One Response

Looks good!